- Name: RAD – Static/dynamic white-beam-neutron and X-ray imaging station

- Technique: Objects in the beam produce attenuation-based contrast on the scintillation screens

- Range of investigated features: 2D and/or 3D macroscopical morphological, structural and real-time process information via static and/or dynamic imaging

- Penetration depth: cm’s

- Typical size of the sample: some or several cm’s

- Measurable materials: Natural and engineered objects (Hydrogen-containing materials)

- Contact: rad@bnc.hu

- Poster of the instrument

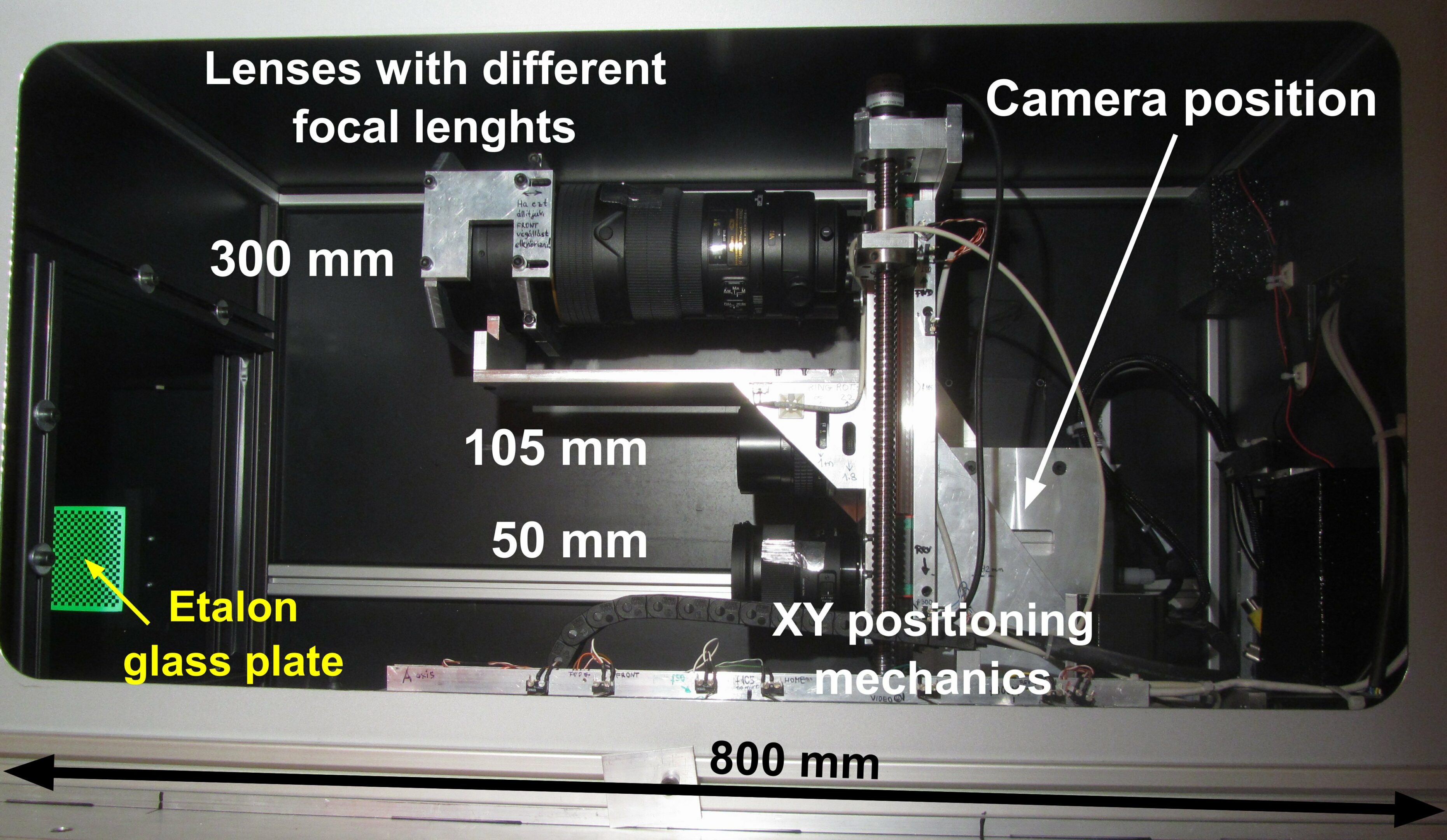

Radiography utilizes the transmission of neutrons and photons to obtain visual information on the structure and/or dynamic processes inside of an object. The facility has variable measurement positions along the neutron beam path with a maximum beam diameter of ~200 mm and is applicable for dynamic (DNR) and static (SNR) imaging. A beam filter wheel with options for thermal (sapphire filter), epithermal (Cd filter), and fast beams (Boron and lead filters) is in place to adjust the energy distribution of the beam. The RAD facility is also equipped with an optional, portable X‑ray tube (up to 200 kVp), allowing dual-modality imaging. Two motorized sample stages, one for small and one for large samples (with a maximum load of up to 250 kg) are available to support the investigated objects. The image detection of the RAD station now relies on digital imaging equipment being able to carry out 2D and 3D imaging using suitable scintillation screens. The spatial resolutions of the available screens are as follows: scintillation screens for neutron radiography with a resolution between 70-250 μm; intensifying screens for X-ray radiography with a resolution of 100-200 μm. Radiography and tomography are accomplished by a large area sCMOS camera, which is interchangeably coupled to the three different optical systems using the lenses with 50 mm, 105 mm, and 300 mm fixed focal lengths. Exposure times range from a few hundredths of a second to a few times tens of a second. For the manipulation, reconstruction, and visualization of the 3D neutron and X-ray datasets (i.e., the tomographic images), the latest Fiji-ImageJ, Octopus 8.9, and VGStudio MAX 3.2 and KipTool software packages are used.

The RAD imaging facility is a versatile system, which makes use of various radiations (thermal, epithermal and fast neutrons, moreover, X-rays) to benefit from their complementary nature, and is used to obtain information on the structure and/or inner processes of a given object. It is utilized for various non-destructive test measurements, on either a static or dynamic system. The system was upgraded as fully digital one in 2014 and was equipped with a neutron filter wheel in 2022 to tailor neutron beams according to applications’ demands. Usually, static imaging is carried out for many types of objects from the field of cultural heritage (e.g., sculptures, swords, ceramics) to engineering objects (e.g., automotive parts, batteries, inserts). There are applications make it possible to visualize and analyse the flow of fluids, the evaporation and the condensation processes in closed metal containers or tube systems, and many other kinds of dynamic events.

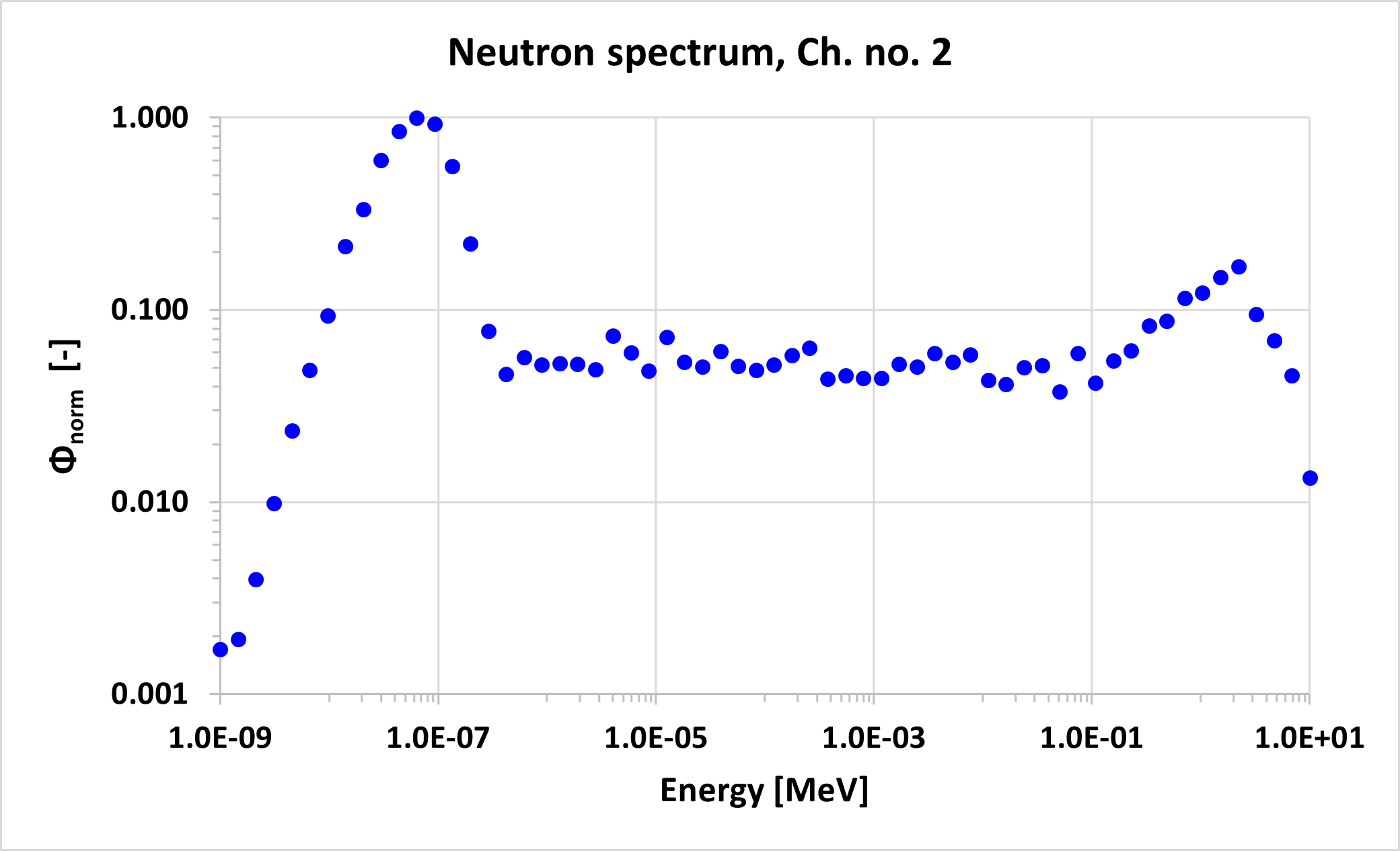

The white-beam neutron imaging facility is served by an in-pile, Cd-covered pin-hole-type collimator placed within the horizontal channel No. 2. When the white beam is filtered by a 150 mm long sapphire crystal filter, a more thermal beam with a thermal neutron flux of 2.92×107 cm‑2s‑1 becomes available at the sample position (the epithermal and fast part of the beam was effectively suppressed to 8.19×103 cm‑2s‑1 and 8.36×105 cm‑2s‑1, respectively).

Beam energy distribution:

Thermal-equivalent flux at target (at different distances):

radial thermal-neutron channel (white beam)

- 4.64×107cm-2s-1 at 209 cm from the beam port

- 3.38×107cm-2s-1 at 259 cm from the beam port

Thermal-to-epithermal flux ratio:

Fast neutron flux (measured with the Ni‑58(n,p)Co-58 reaction):

51

2.7×107cm-2s-1 at 209 cm

Collimator ratio (L/D) :

Gamma dose rate:

X-ray sources:

Field of view options:

210 – 250

8.5 Gy/h

5-200 keV; 5-10 mA

41×34 mm2, 110×93 mm2 or Ø200 mm

Scintillator screens (thicknesses):

- Li6F/ZnS:Cu (100, 200, 225, and 450 µm)

- 10B2O3/ZnS:Cu (50 µm)

- Gadox P43 (10 µm)

- 3-mm thick PP/ZnS(Ag) for fast neutrons

- CAWO OG2 and OG8 intensifiers for X-rays

Mirror:

Al coated quartz mirror set at 45° to the beam

Optics:

- Sigma 50 mm f/1.4 DG HSM ART

- Nikon-Nikkor 105 mm f/1.8

- Nikon AF-S 300 mm f/2.8 G ED VR II

Imaging detector:

Andor Neo 5.5 sCMOS camera with 2560×2160 pixels and 16-bit pixel depth

Spatial resolution:

70‑250 μm depending on the FOV and scintillators

Exposure times:

- 1-35 s per image

- 601 – 1001 projections for a tomogram

- 25 fps for dynamic measurements

Sample stages:

- motorized sample stage for heavy objects up to 250 kg

- ω turntable for 3D imaging up to 5 kg

Fig. 1 The normalized neutron energy spectrum of the RAD facility based on MCNP simulation

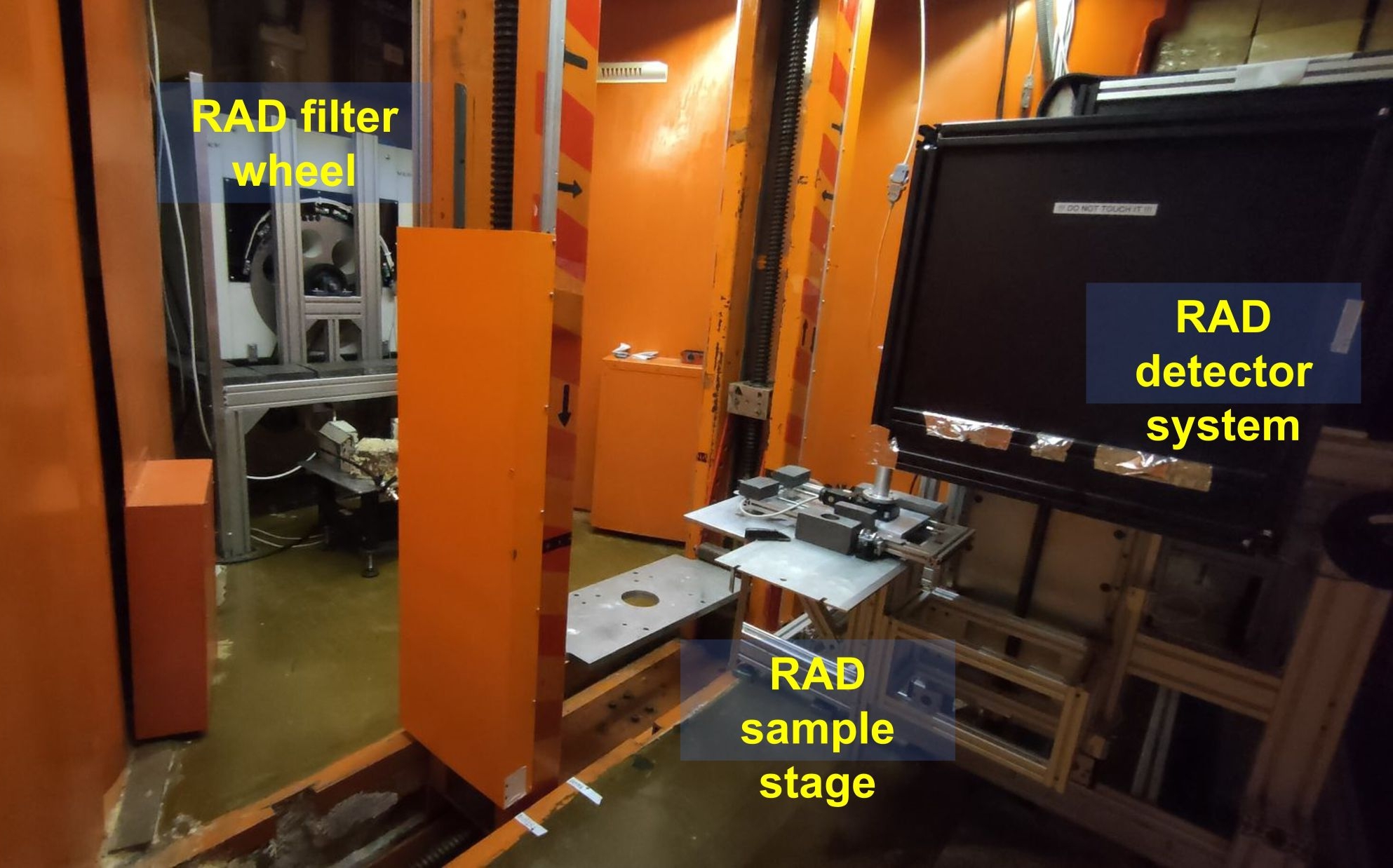

Fig. 2 The outer view of the RAD bunker and control room showing the basic layout of the facility

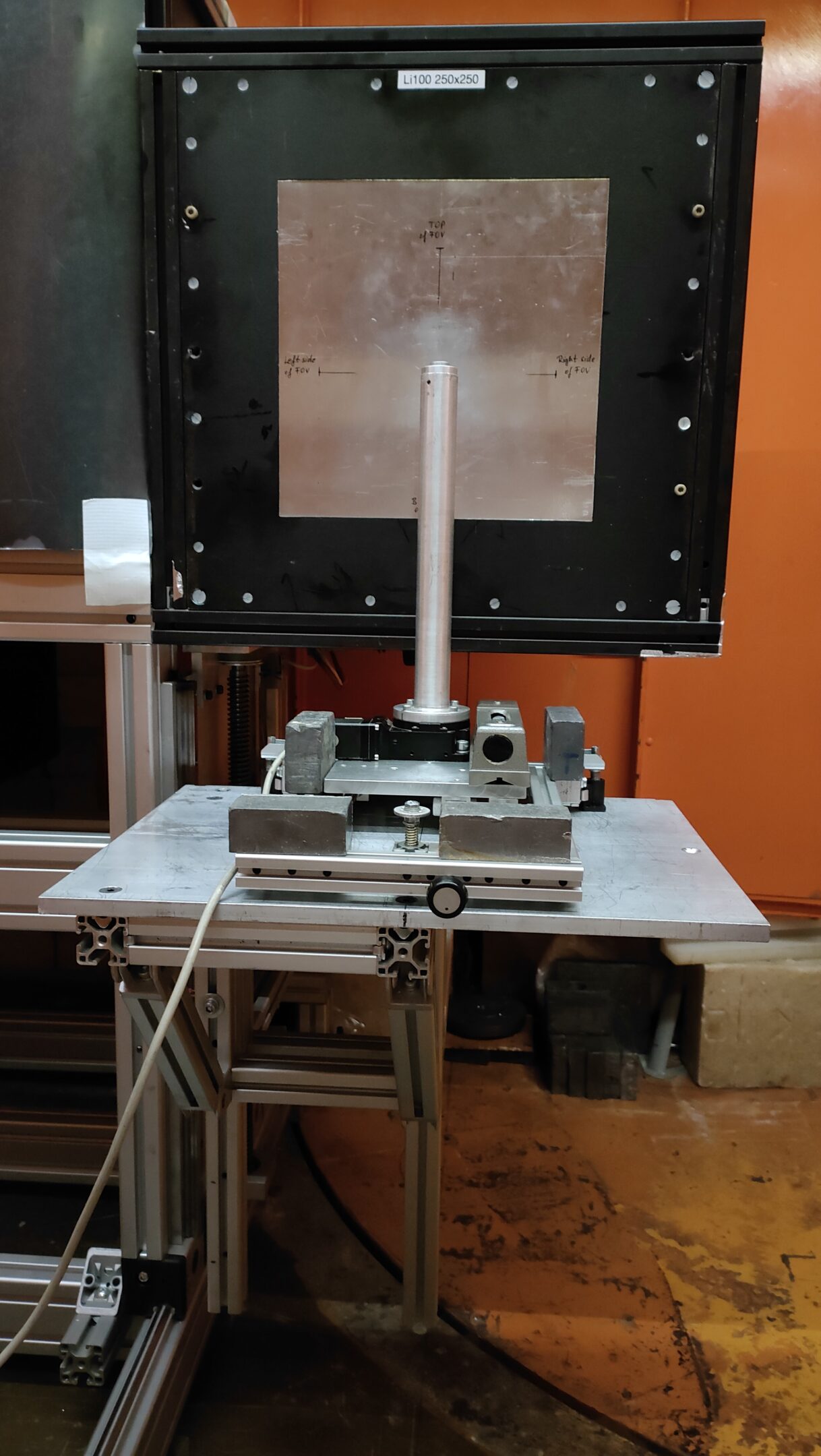

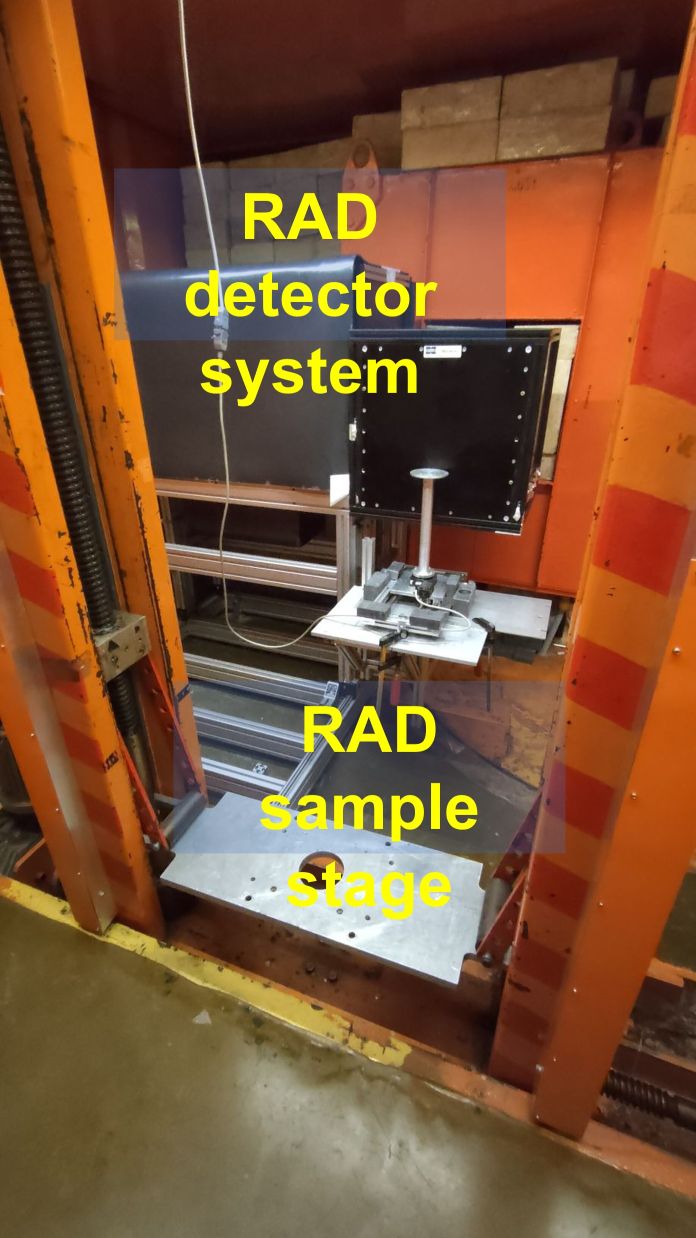

Fig. 3 The inner view of the RAD bunker

Fig. 4 and 5 The digital imaging system of RAD and the sample manipulators for heavy or small objects

Fig. 6 The optics of the detector system

Article about the instrument in more detail:

Z Kis, L Szentmiklósi, T Belgya, M Balaskó, LZ Horváth, B Maróti. Neutron-based imaging and element-mapping at the Budapest Neutron Centre, Physics Procedia. 69 (2015) 40 – 47. DOI: 10.1016/j.phpro.2015.07.005