- Name: REF – Neutron Reflectometer

- Technique: constant wavelength specular reflectometry

- Range of investigated features: determination of planar structure of multilayers, characterization of neutron optical devices (e.g. neutron supermirrors and Bragg mirrors)

- Penetration depth: incidence angle dependent

- Typical size of sample: length: 20-50 cm, height: 2-20 cm, typical thin film thickness: 0.1-10 µm

- Measurable materials: solid thin films, metal multilayers on various substrates (glass, metal)

- Contact: ref@bnc.hu

- Poster of the instrument

This instrument is a constant wavelength type reflectometer. During the measurement the sample is rotated around a vertical axis and the reflected neutrons are detected in the function of incidence angle. The method makes possible the determination of planar structure of multilayers i.e. layer thicknesses, roughnesses, scattering length densities. The reflectivity curve directly characterizes the neutron optical properties of neutron supermirrors and Bragg mirrors manufactured for neutron delivery systems.

The reflectivity characterize the quality of neutron optical devices (e.g. neutron supermirrors and Bragg mirrors) for neutron delivery systems. The reflectivity measurement gives information about the scattering length density in the function of the depth from the sample surface. The intensity of the specularly refleced beam can be calculated using the Parratt method or matrix method based on the continuity of the wave function and its derivative at the interfaces. One can build a modell for the thin film structure and the scattering length density profile can be determined by iterative improvement of the modell. In the case of monolayers or periodic multilayers the layer thickness and roughness can be determined by a few Å accuracy. As slow neutron scattering experiment the method is non-destructive.

The neutron reflectometer (REF) located in the cold neutron hall, on guide 10/1.

The main components and schematic view of the REF neutron reflectometer

The instrument operates at constant wavelength λ = 4.28 Å. The monochromator system selects this wavelength from the continous spectrum of the neutrons delivered by the guide.

Due to space restrictions in the experimental hall, the neutron path had to be aligned parallel with the guide. Therefore a double monochromator system was installed. In order to increase the neutron flux on the sample, the monochromator elements(PG crystals of 0.4° mosaicity) are are arranged in a special focusing geometry displayed in the next figure.

The scheme of the focusing arrangement of the two monochromator and the slits

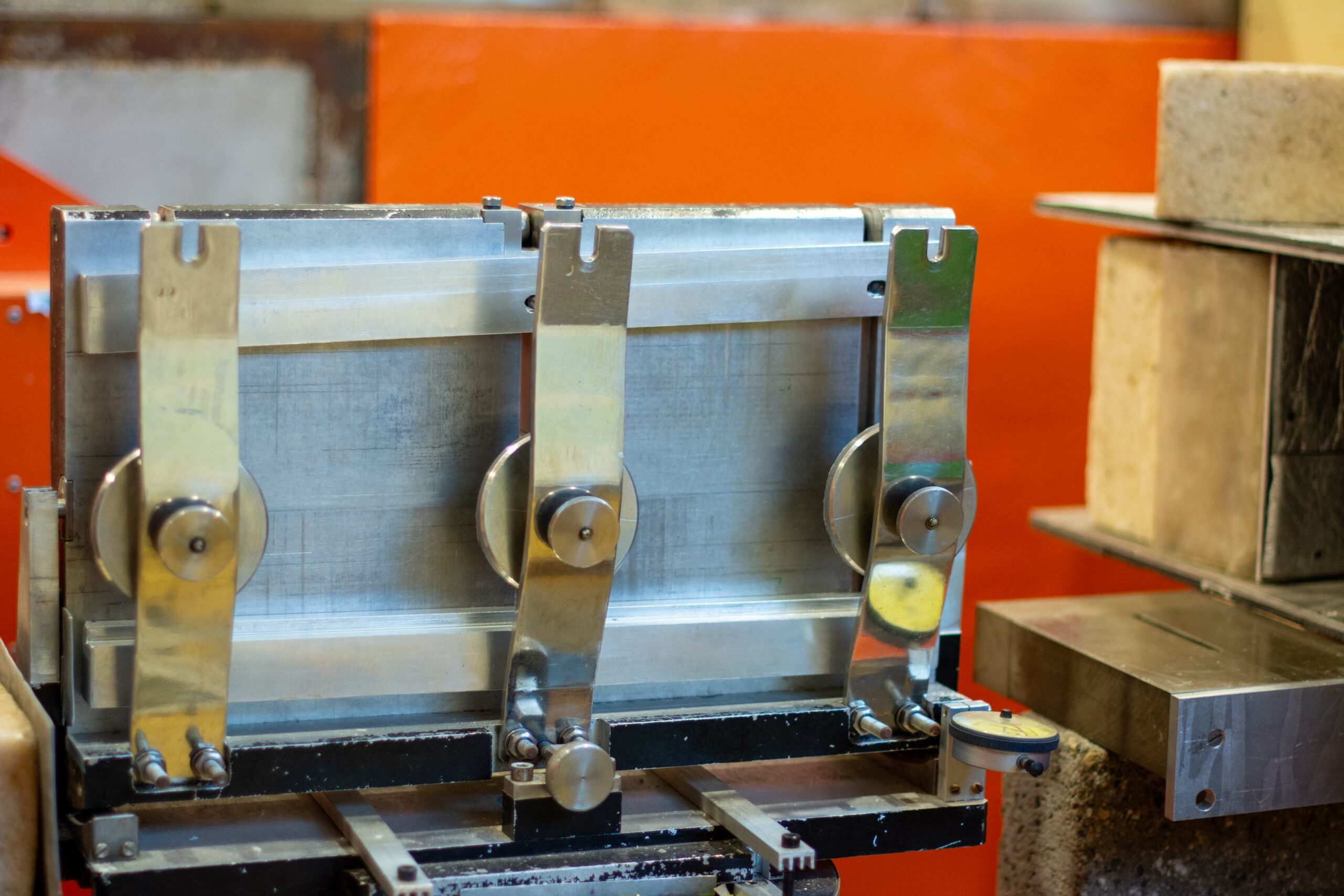

The higher harmonics of the l = 4.28 Å are filtered out using a Be filter (cooled by liquid N2 to reduce loss caused by phonon scattering) positioned between the two monochromators. The collimation is provided by two slits (usual slit width 1 mm) in 2000 mm from each other. The sample is mounted on the sample holder and can be rotated around a vertical axis with 0.0055° accuracy. The sample length is 10-70 cm and the height 2-25 cm, the maximal thickness is 2 cm. During measurement the sample is pressed by a massive glass plate to two adjustable metal bars determining a plane containing the rotation axis. Due to this construction there is no need of further sample alignement process after sample change. However a regular instrument calibration is performed.

The reflected neutrons are detected using a position sensitive 3He detector, with active area 20×20 cm2. In the case of large (10 cm height) samples the smallest measurable reflectivity is 0.0005.